WBF – Balloon purified water washing, filling and capping equipment

A Ballonos tisztított víz mosó-,töltő-, és kupakológép a Györök Kft. által fejlesztett komplex és hatékony rendszer. Viszonylag kis helyigényű teljes szolgáltatást nyújtó berendezés, a tisztított víz hatékony, 19 literes ballonokba való töltésére.

WBFC – Balloon purified water washing, filling and capping equipment

The WBFC balloon water bottling machine is the ideal choice for medium-capacity plants. Thanks to its compact design, it requires little space, is easy to install, and can be easily integrated into existing production systems.

The machine consists of three main units: two separate washing and rinsing modules, and a filling and capping unit. The entire bottling process can be carried out on a single machine – washing, rinsing, filling, and sealing the bottles all take place within one system.

The user interface is equipped with a modern PLC display, which allows all important parameters – such as load size, wash and rinse times, and other operating settings – to be set easily, quickly, and accurately. Operation is user-friendly, with individual functions activated at the touch of a button.

The equipment is made of stainless steel, thus meeting hygiene requirements and ensuring a long service life. The WBFC is an excellent solution if you are looking for an easily controllable, customizable, and compact balloon water filling device.

The price of commissioning the equipment and training the operating personnel is not included in the offer!

The handover of the equipment will take place at the premises of Györök Ltd.!

Capacity: 90-100 bottles/hour

Washing: inside and outside, hot chemical wash, rinsing in two separate compartments

Filling: using a flow meter, precisely adjustable filling quantity

Closing: automatic, manual cap filling

Detergent temperature: max.: 60 °C (adjustable)

Detergent temperature: max.: 60 °C (adjustable)

Required water quantity: 3600 l/h

Required air quantity: 160 l/s, 5 bar

Electrical connection: 400 V, 50 Hz, 11 kW

External dimensions (LxWxH): 1610x600x1950 mm

Weight: approx. 280 kg

Optional extras for WBFC:

– UV sterilization equipment

– Daily tank

– Compressor

– Chemical dosing system

– Installation and training

WBFL– Balloon purified water washing, filling and capping equipment

The biggest advantage of the WBFL balloon water bottling equipment is that it is extremely compact design, így easy to install, and requires minimal space within the plant It consists of two main units: washing and rinsing module (1x) and a filling and capping unit, which efficiently completes the bottling process. It is particularly user-friendly, as each function can be started at the touch of a button, thus simplifying operation. (1x), valamint egy töltő és kupakoló egységből, amely a palackozási folyamatot hatékonyan zárja le. Működtetése különösen felhasználóbarát, hiszen egyetlen gombnyomással indíthatóak el az egyes funkciók, ezzel is leegyszerűsítve a kezelést.

The device operates with a pre-programmed filling quantity, which ensures accurate and consistent filling of the bottles. The entire machine body is made of stainless steel. The WBFL can be easily connected to the existing water supply and seamlessly integrated into existing production processes. Thanks to its complex yet well-designed system, a single device can cover the entire bottled water filling process, from cleaning to sealing the bottles. előre programozott töltési mennyiséggel dolgozik, amely biztosítja a palackok pontos és egyenletes feltöltését. A teljes géptest rozsdamentes acélból készült. A WBFL egyszerűen csatlakoztatható a meglévő vízhálózathoz, és zökkenőmentesen integrálható a már kialakított gyártási folyamatokba. Komplex, mégis átgondolt rendszere révén egyetlen berendezéssel lefedhető a teljes ballonos víz palackozási folyamat, a tisztítástól egészen a ballon lezárásáig.

Compared to the WBFC, it only has a washing and rinsing unit, so its average capacity is half as much.

The price of commissioning the equipment and training the operating personnel is not included in the offer!

The handover of the equipment will take place at the premises of Györök Ltd.!

Capacity: 50-60 bottles/hour

Washing: inside and out, hot chemical wash, rinsing

Filling: using a flow meter, precisely adjustable filling quantity

Closing: automatic, manual cap filling

Closure: automatic, with manual cap filling

Detergent temperature: max: 60 °C (adjustable)

Required water volume: 2500 l/h

Required air volume: 100 l/s, 5 bar

Electrical connection: 400 V, 50 Hz, 4.5 kW

External dimensions (LxWxH): 1300x600x1950 mm

Weight: approx. 280 kg

Optional extras for the WBFL:

– UV sterilization equipment

– Daily tank

– Compressor

– Chemical dosing system

– Installation and training

WBFH – Balloon purified water washing, filling and capping equipment -for smaller businesses

The WBFH is an affordable, compact device developed specifically for smaller plants to fill a small number of cylinders. It consists of three main units: a washing and rinsing module, a filling unit, and a manual capper. It is extremely easy to use—all functions can be activated with a single button press, making it quick to learn and easy to operate.

The machine operates based on a preset filling time, so each balloon receives the same amount of water without any unnecessary adjustments. Stainless steel design makes it a durable and hygienic solution.

The WBFH is compact, quick to install, and easy to connect to your existing water network, making it the ideal choice if you are looking for a simple, reliable, and economical bottling solution for smaller-scale production.

The price of commissioning the equipment and training the operating personnel is not included in the offer!

The handover of the equipment will take place at the premises of Györök Ltd.!

Capacity: 25-30 bottles/hour

Washing: inside and out, hot chemical wash and rinse

Charging: charge amount can be set by time

Closure: manual cap placement and pressure

Detergent temperature: max.: 60 °C (adjustable)

Required water volume: 2500 l/h, at a pressure of 3-4 bar, 2×1/2”

Required air volume: 100 l/s, 5 bar

Electrical connection: 400 V, 50 Hz, 4.5 kW

External dimensions (LxWxH): 1300x600x1950 mm

Weight: Approx. 120 kg

Optional extras for the WBFH:

– UV sterilization equipment

– Daily tank

– Compressor

– Filling pump

– Installation and training

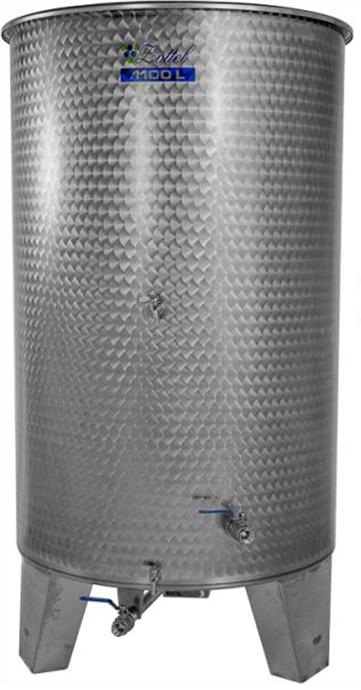

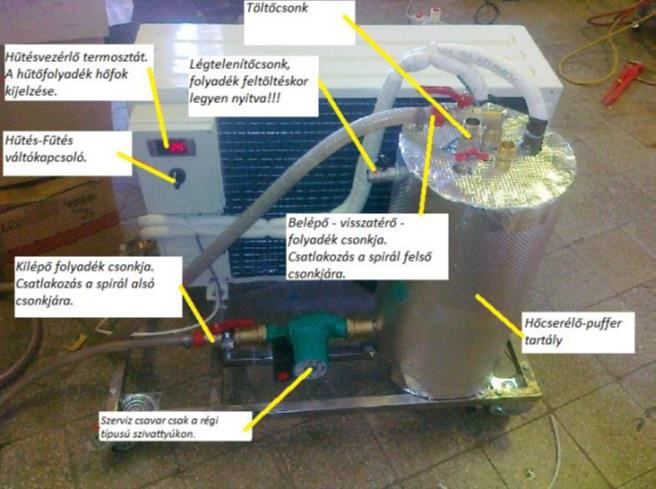

J-BOR IK5/AMPO 600/1000/1100 l, ivóvíz hűtő berendezés

A 600, 1000 vagy 1100 literes tartály hőcserélő spirállal egy professzionális, rozsdamentes acélból készült berendezés, melyet szikvízgyártáshoz terveztek, nagy mennyiségben biztosítja a lehűtött víz tárolást és a hőmérséklet szabályozását.

The tank complies with relevant food industry standards, and its cylindrical design and reinforced structure guarantee durability and safety. The built-in heat exchanger coil is made of stainless steel and supports efficient heat transfer to maintain the water at an optimal temperature, ensuring maximum carbon dioxide saturation.

The high capacity of the equipment allows for continuous production, while its energy-efficient operation reduces operating costs. Its hygienic design ensures easy cleaning, making it ideal for small and medium-sized sparkling water production plants.

Cooling capacity, maximum: 12.0 kW (outlet antifreeze temperature 5.0 °C)

Hűtés min. Termék hőfok: +2,0 °C-ig

Fűtőteljesítmény, névleges: 14,6 kW

Max. electrical power consumption in cooling mode: 4.2 kW

Villamos betáp, fázis: 400 V/3/50Hz

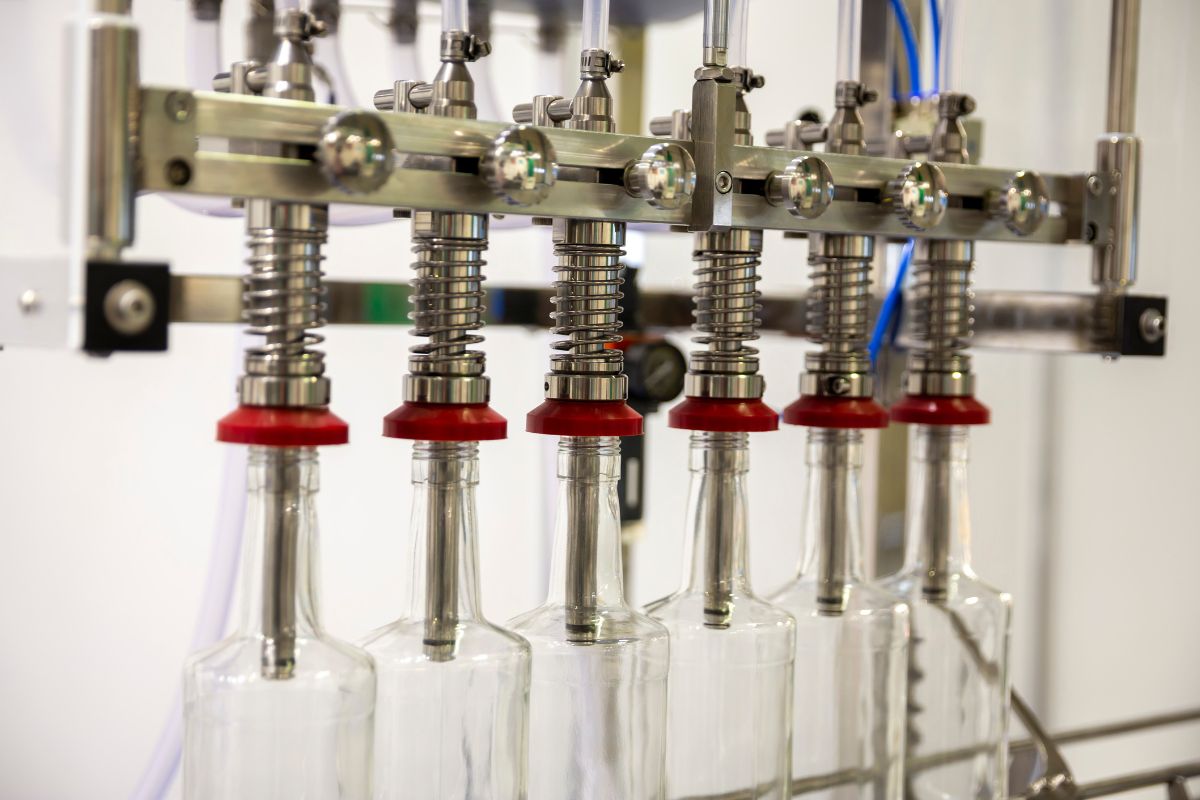

Víztöltő gép

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse vitae cursus velit, sit amet pulvinar diam. Cras id urna rutrum, dictum mauris eget, lacinia magna. Sed commodo enim sed consequat varius.

Weight of the machine: 96 kg

Electrical power requirement:

– Power 0.75 KWh

– Feszül 220 V

– Frekvencia:

Machine operation: Automatic

Get a quote