complete, personalised

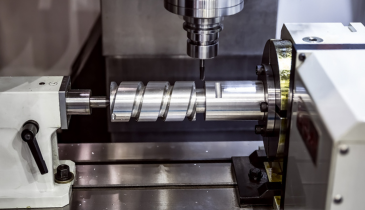

Soda Water Production Facilities

planning and installation

We offer complete, professional solutions for the construction of sparkling water plants. By combining state-of-the-art technology with precision engineering, we provide equipment that guarantees economical and reliable operation.

Ask for a Custom Offer

outstanding quality and reliability

Our machines are designed, manufactured and tested to the highest quality standards.

Full Installation

and maintenance

We install and commission the machines ourselves and undertake regular maintenance of the soda water machines to ensure reliable production.

development and

innovation

We use the latest manufacturing technologies and trends to ensure that our machines meet all specifications.

Does setting up a production plant raise a lot of questions for you too?

Unsure about the costs you should expect when setting up your plant?

Not sure which equipment best suits your production goals?

Worried about the long-term reliability of your machines and potential downtime?

Are you worried that complying with regulatory requirements and industry standards might be complicated and time-consuming?

Do you want to avoid delays but feel unsure about the entire commissioning process?

If so, Ampo is your perfect partner!

Our services are designed to adapt to your specific needs. Whether it’s planning, consulting, or implementation. We support you every step of the way!

Ask for a Custom Offer

modern plant in 5 steps

1. Consultation

2. Survey

3. planning

4. Execution

5. maintenance

comprehensive solutions From design to implementation

Setting up a soda water production plant is a complex yet highly manageable task, based on the precise coordination of technological requirements, production capacity, and regulatory compliance. Selecting the right equipment, building the necessary infrastructure, and optimizing the production process all contribute to the creation of an efficient, reliable, and sustainable facility. Whether you're establishing new production capacity or upgrading an existing system, the objective remains the same: to ensure safe, cost-effective, and high-quality production

1. CONSULTATION

Our experts conduct a thorough assessment of your needs and production requirements to deliver the most optimal solution for setting up your plant. We discuss capacity demands, available infrastructure, and industry regulations in detail to ensure everything is aligned with your goals.

2. SURVEY

We will carry out an on-site analysis of the site conditions, the technical conditions of the building and the energy supply options. Our aim is to ensure that the equipment is installed and commissioned as efficiently as possible.

3. PLANNING

Every step of the installation is carefully planned to ensure that the layout, wiring and integration of the machines is as optimal as possible. Efficiency and legal compliance are paramount.

4. EXECUTION

Our experienced professionals will install the plant to the highest industrial standards. From the installation of the machinery to the trial run, we ensure that all equipment is working properly and ready for production. All machinery and equipment is handed over with practical training for the Buyer on installation, operation and maintenance.

5. MAINTENANCE

We won’t leave you on your own after installation! Upon request, we provide maintenance and service support to ensure that your plant continues to operate reliably and efficiently in the long term, with minimal downtime. Our regular inspections help prevent malfunctions, while our fast and responsive service ensures uninterrupted operation, so you can always focus on production.

You can finally leave all that behind:

Outdated, hard-to-use, unreliable equipment— You no longer have to worry about constant breakdowns and frequent downtime.

Unnecessary production losses— A more efficient plant means less waste and higher profits.

Chaotic workflows— A modern, well-designed plant ensures smoother and more predictable production processes.

High maintenance and repair costs— Energy-efficient, modern machines deliver significant long-term savings.

Ongoing compliance issues— With technologies that comply with the latest regulations, you no longer have to worry about inspections.

30+

years of experience

100%

customer satisfaction

100+

happy customer

500+

installed production unit

Our customers say we know what we're doing

See what our clients are saying after placing their machinery projects in the expert hands of AMPO!

Their satisfaction is the best proof of our collective success.

Our Mission

Az AMPO márka története Ampovics Zsolt elhivatottságával és szakértelmével kezdődött, aki évtizedeken át fejlesztette és tökéletesítette a szikvízgépek gyártását. Az ő munkássága alapozta meg az AMPO minőségét és megbízhatóságát, amelyet 2024 végén a Györök Kft. vett át, hogy továbbvigye ezt az örökséget. Az átvétellel ötvöztük az AMPO hagyományait és szaktudását a Györök Kft. mérnöki precizitásával és szemléletével.

Our aim is to continue to deliver the reliability you have come to expect from AMPO machines, while constantly adapting to modern food industry requirements through continuous improvements. Whether it's the manufacture of new equipment, the maintenance of existing machines or the design of complete plants, we support our partners with our expertise and dedication.

Our Managing Director, Zsolt Györök, with his personal experience and decades of working with Zsolt Ampovics, will ensure that the brand's tradition continues in a worthy manner.

Full company history

Our clients

Contact us!

If you have any questions, or if you're interested in our products and services, you can easily reach out to us using our contact form.

"*" indicates required fields